Monday night I worked all evening to make some nice aluminum brackets for our test valve.I went to bed at 12:30 and got up at 5:45 to keep my appointment at the Gym.By Tuesday evening I was useless and did no work. I see its going to be a challenge toboth keep the commitment and to throttle the effort so as not to burn out.Today I finally got the FAA to engage in some discussion and learned a valuable fact.They are much more open to talk rather than respond to E-Mails as it leaves no record.I've scheduled a conference call for 9:am EST Thursday (6 am here) so maybe I'll finally make some progress. My agenda for the call is as follows:Three specific Items I'd like to discuss, and a few more if time and personal permit.

1)Is my concept of having two redundant flight termination systems

that are completely separate from the vehicle operations hardware and software acceptable?

Specifically:

System 1 continuously calculates the instantaneous impact point at 5Hz

and terminates the flight if the IIP hits the predefined defined boundary.

System 2 Is a commercial PCM RC receiver that terminates the flight on command or on loss of signal.

2)What limitations are necessary for staying within the 14.99999 second rule.

Can I carry more than 14.999999 seconds of fuel with a hardware timer that terminates

thrust after 14.999999 seconds of burn time?

Is sensing valve position sufficient to establish burn times?

Is a post burn cool down purge with water and/or inert gas counted against the burn time?

I want to test the vehicle at full gross takeoff weight with the same dynamics as

a fully fueled vehicle. I'd rather not have separate non-sloshing weights as this is an

unrealistic test.

I'd like to set up two temporary metal road plate pads at FAR and

3)What are the requirements for tethered operation?

Rather than do serious worst case mechanical tether analysis can I have the tether carry an electrical circuit, if the

circuit is broken terminate the flight.

Additional items...

Hardware design items:

My intent is to make the safety termination systems separate isolated battery powered

units. The only external connection will be a fiberoptic status output so the units can report battery condition

and self test completion to the outside world. Fiberoptic is chosen as there is no physical way to transmit

electrical transients back into the units that will kill them.

I plan to do full environmental shake and bake qualification on all safety termination systems.

I'd prefer to do this with self constructed temperature chambers and vibration tables,

but If more formal methods are required I'm familiar with the process as I used to run a

"shake and bake" environmental stress screening operation that tested avionics for the Navy.

How would the FAA like to see positional IIP limits input into the system

Some possibilities:

Physically carry the box to the boundaries of the termination area.

Establish a center point by physically transporting the box there and then draw boundaries.

Enter the boundaries from a map or other source of geographic data.

Can the boundaries be simple rectangles?

Convex polygons?

I realize that calculation of Ec is not required for an experimnetal permit, but I expect that one will be done

in any case. Is there any benefit in qualifying sub components in a real world environment and

demonstrating a low probability of failure, showing operational reliability by test?

I'm thinking about putting the navigation,stability,control, and safety termination systems on a RC helicopter

and having them fly vehicle competition profile hundreds or even thousands of times.

Any benefit in having a RC plane or helicopter fly the boundaries of the IIP box for visual verification?

From todays phone conversation it is clear that the FAA does not like my choice to

do all my testing at FAR under the 15 second rule. With a limited budget I just can't afford

to do it a Mojave without some external funding. If we get to the point where that becomes necessary maybe we will have enough visible results to attract some funding.

Specific Progress Tuesday and Wedensday

I finished up the PCB design for my helicopter tester.

I hope to fly an RC helicopter with the same telemetry and control as the rocket and

start testing and writing the command and control software. I will see is my tine Trex 400 can lift the equipment otherwise I will need to buy something bigger.

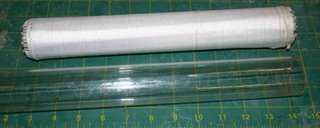

Tonight I hope to finish my first drill driven prototype valve.

Paul