Saturday I spent the day at the FAR//MTA site. I was working on some forms for another storage container at FAR. I'm on my knees digging in the desert sand with my hands to make room for the form , and I realized that building rockets this way was a lot like grilling a hamburger where the first step was to plant the grass to feed the cow....

The RRS was having its Christmas party the same day and the RRS/MTA had a few interesting things going on. I'm not all that taken with the unguided HPR soldis and hybrids they remind me of artillery. I did find the large 4000 lb thrust Lox methanol that was test fired interesting.

As Keven said "That was a manly sound" If you have ever heard a liquid rocket fired it is a sound that you will never forget. No recording I've ever heard did it justice.

A number of bits and pieces arrived this week. I got the solenoid valves I ordered from

Predyne I got 6 valves in two different sizes these will be used for building an igniter and doing purges. Unlike Snaptite, predyne will sell in small quantities to normal people. So I can get more valves when I need them.

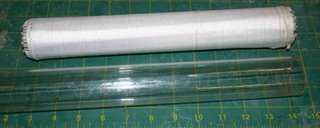

I also received my stainless steel Hemispheres from AMS industries to build some spherical stainless tanks.These are 18" diameter 316 Stainless. the thinist point is about 0.064 thick.

My son has finals next week, when that is done He will weld them up and we will hydro test them. I plan to use the same strap technique that Armadillo used to align them. (Thanks John for being so open and public!)

Lastly I spent Sunday working on my personal skills. As I indicated in my post on the CNC myth it takes skills to build things using CNC machines. I've spent about 18 months working with small CNC mills, but I have almost no time using a CNC lathe. So I spent the day with some scarp aluminum bar stock turning things to diameters and then making threads.

the straight threads took my 5 tries to get right... After I had all the bugs in that worked out

I made some tapered NPT pipe threads. I got that right on the first try. It does not look like much but the results:

Straight thread on the bottom and tapered pipe thread on the top.

The pipe thread is longer than it needs to be, but the taper is correct.